Stryker Inflatable Boats has been building the toughest, safest, most well equipped and versatile boats in the industry since 2004. Our customers include Fire & Police departments, Search & Rescue, Military, Industry Professionals, Fishermen, Hunters, Guides and People like you, in search of a finely crafted, dependable vessel that they can rely on year after year.

Since 2004 we have been boat enthusiasts. Being on the water is what we love to do. By taking our passion into this business we’ve created what we and many of our customers believe to be an amazing boat with all the accessories you’ll need for a competitive price.

PVC pad and safety belt for your gas tank secured with heavy duty stainless steel d rings.

The Stryker LX inflatable boats come with 6 interior d rings and the Stryker HD & PRO have 10 interior d rings. You can use these for securing cargo inside. They are specially positioned to work with a Stryker Swim Ladder or Stryker Essential Bag.

Every Stryker Inflatable Boat comes with a heavy duty full wrap around life line. This is essential for the safety and security of passengers while under way in the vessel and during emergency situations.

On every Stryker Inflatable Boat the seating area is reinforced with 1.2mm PVC for the Stryker LX models and 1.8mm PVC for the Stryker HD & PRO models. With this added layer of material, you can rest assured vthat your inflatable boat is protected in high wear areas.

Every Stryker Inflatable Boat comes with a heavy duty 1680D material for your aluminum floor pieces. We’ve found the best way to transport your floor is separate from the boat.

A simple cross design boat bag also doubles as a tarp while setting up your Stryker Inflatable Boat. Our new 1680D material offers increase strength and wear resistance.

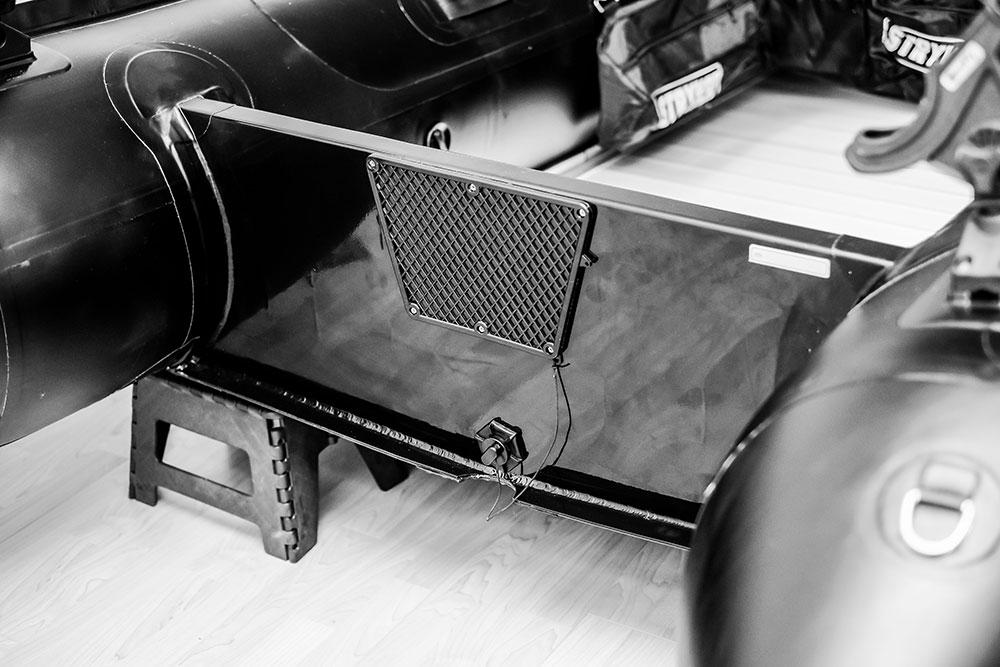

All Stryker Inflatable Boats come with 2 HD lifting eyes/tow rings welded to the exterior of the transom.

Every boat comes with standard high volume pump. Airmat boats get a hand pump!

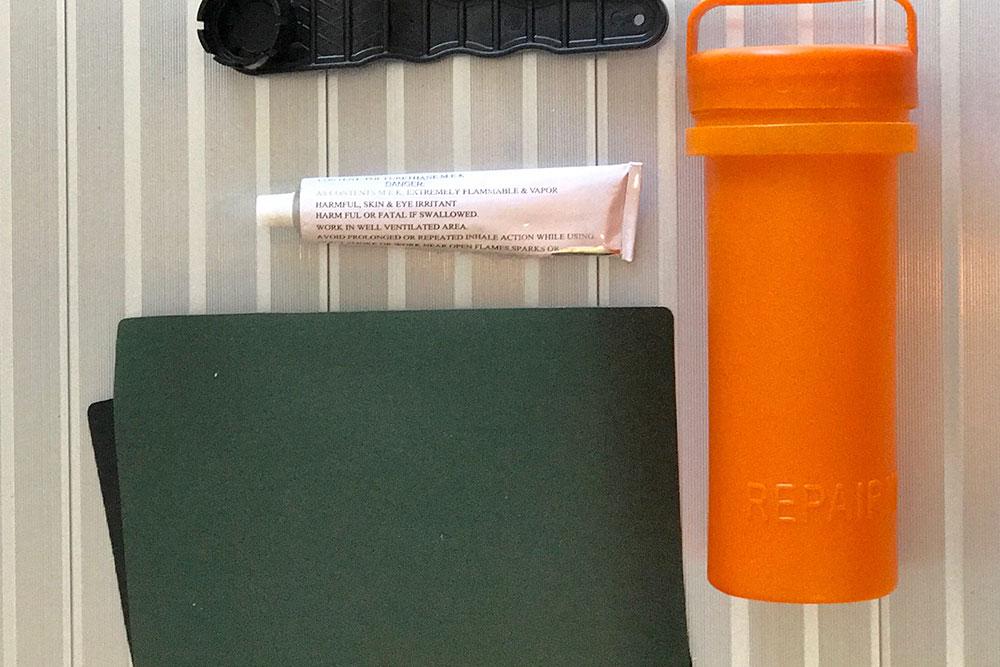

Accidents can happen! Each kit comes with 2 pieces of PVC, a tube of glue and a valve tool to tighten up valves that sometimes get loose.